Developments in Offset Lithography

We’ve come a long way from the stone plate. As you can well imagine, it would be very difficult to mount a piece of stone on modern high-speed presses. Senefelder's first press was flat, so the use of stone was easy. Today's presses use curved cylinders to hold the offset plates.

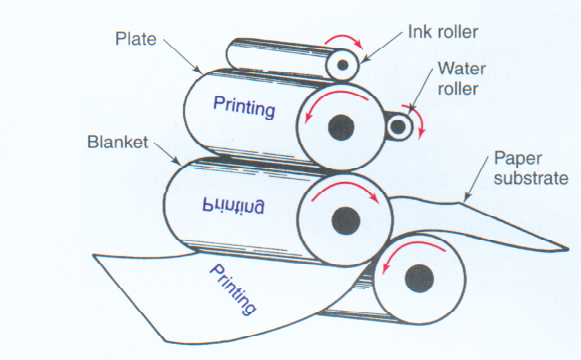

The basis of modern lithography is a combination of photography and Senefelder's original observation that "oil and water do not mix." All offset plates made today employ this offset principle, they use as an image carrier such as thin paper, plastic, or a metal sheet which once exposed and processed can be wrapped around a cylinder of a press for printing. This modern offset plate contains two areas; image areas, which repel water (remain dry and accept ink) and non-image areas, which accept water. This is the basic requirement of all modern lithography - the ability to produce a plate that will have image areas that are "hydrophobic" (meaning water hating) and non-image areas that are "hydrophilic" (meaning water loving). While the basic principle is common, there are many differences between offset plates and the method they use to separate the image from the non-image areas.

The

image above shows that the plate is "right reading" or that

the plate reads correct, from left to right. The image is transferred

to the blanket cylinder (or "offset") to "read wrong"

or backwards (a mirror image). Finally, the image is printed "read

right" onto the paper.