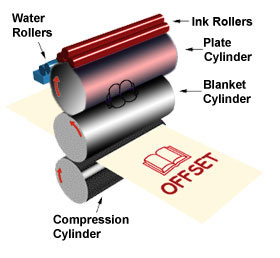

The offset printing process:

The image to be reproduced is made on a thin metal plate.

The thin metal plate is wrapped around the plate cylinder.

The plate is wetted with water.

The water adheres to the background area but not to the image.

After wetting, the rotating plate cylinder is inked.

The greasy ink sticks to the dry image but not to the wet background.

Continuing to revolve, the plate is pressed against another cylinder

bearing a rubber blanket.

The rubber blanket picks up the ink from the plate and transfers (offsets)

it to the paper.